- Home Page

- Company Profile

-

Our Products

- Stainless Steel Sheet

- 304 Stainless Steel Sheet

- Stainless steel 202 Sheets

- Stainless Steel Sheet

- 430 Stainless Steel Sheet

- X2crni12 Stainless Steel Sheets

- X5crni1810 Stainless Steel Sheets

- 316 Stainless Steel Sheet

- 321 Stainless Steel Sheet

- 410 Stainless Steel Sheet

- 420 stainless steel sheet

- 904l Stainless Steel Sheet

- 202 Stainless Steel Sheets

- 301 Stainless Steel Sheets

- 304L Stainless Steel Sheets

- 316L Stainless Steel Sheets

- 310 Stainless Steel Sheets

- 310S Stainless Steel Sheets

- 309 Stainless Steel Sheets

- 309S Stainless Steel Sheets

- 316Ti Stainless Steel Sheets

- 409M Stainless Steel Sheets

- 409L Stainless Steel Sheets

- 441 Stainless Steel Sheets

- DUPLEX Stainless Steel Sheets

- DUPLEX 2205 Stainless Steel Sheets

- DUPLEX 2507 Stainless Steel Sheets

- HASTALLOY Stainless Steel Sheets

- INCONEL Stainless Steel Sheets

- X2CRNI12 Stainless Steel Sheets

- X5CRNI1810 Stainless Steel Sheets

- 253 MA Stainless Steel Sheets

- 16MO3 Stainless Steel Sheets

- Stainless Steel Coils

- 202 Stainless Steel Coil

- 316 Stainless Steel Coil

- 304L Stainless Steel Coil

- Industrial Stainless Steel Coil

- Stainless Steel Coil

- X2crni12 Stainless Steel Coils

- X5crni1810 Stainless Steel Coils

- Stainless Steel Slitting Coil

- 309 Stainless Steel Coil

- 201 Stainless Steel Coil

- 409 Stainless Steel Coil

- 410 Stainless Steel Coil

- 430 stainless steel coil

- 904l Stainless Steel Coil

- 301 Stainless Steel Coil

- 304 Stainless Steel Coil

- 316L Stainless Steel Coil

- 309S Stainless Steel Coils

- 310 Stainless Steel Coils

- 310S Stainless Steel Coils

- 316Ti Stainless Steel Coils

- 409M Stainless Steel Coils

- 409L Stainless Steel Coils

- 321 Stainless Steel Coils

- 441 Stainless Steel Coils

- DUPLEX Stainless Steel Coils

- DUPLEX 2205 Stainless Steel Coils

- DUPLEX 2507 Stainless Steel Coils

- HASTALLOY Stainless Steel Coils

- INCONEL Stainless Steel Coils

- 253 MA Stainless Steel Coils

- X2CRNI12 Stainless Steel Coils

- X5CRNI1810 Stainless Steel Coils

- 16MO3 Stainless Steel Coils

- Stainless Steel Plate

- 316 Stainless Steel Plate

- 304 Stainless Steel Plate

- Stainless Steel Plates

- Duplex Stainless Steel Plate

- 409 stainless steel plate

- 410 stainless steel plate

- 420 stainless steel plate

- 904l stainless steel plate

- 202 Stainless Steel Plate

- 304l Stainless Steel Plate

- 316L Stainless Steel Plate

- 321 Stainless Steel Plate

- 310S Stainless Steel Plate

- 309 Stainless Steel Plate

- 309S Stainless Steel Plate

- 316Ti Stainless Steel Plate

- 430 Stainless Steel Plate

- 441 Stainless Steel Plate

- DUPLEX 2205 Stainless Steel Plate

- DUPLEX 2507 Stainless Steel Plate

- INCONEL Stainless Steel Plate

- HASTALLOY Stainless Steel Plate

- X2CRNI12 Stainless Steel Plate

- X5CRNI1810 Stainless Steel Plate

- 253 MA Stainless Steel Plate

- 16MO3 Stainless Steel Plate

- Stainless Steel Pipes

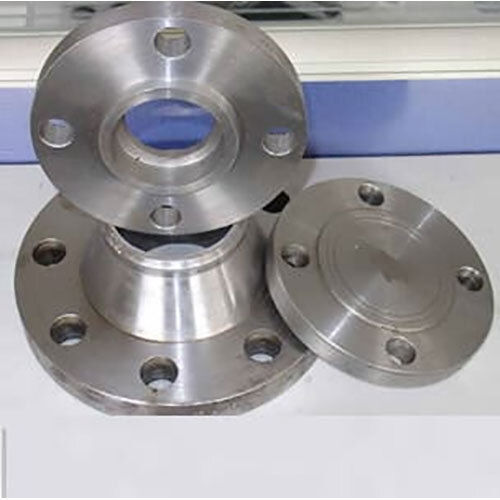

- Stainless Steel Flanges

- Stainless Steel Flange

- 202 Stainless Steel Flanges

- 304 Stainless Steel Flanges

- 304L Stainless Steel Flanges

- 316 Stainless Steel Flanges

- 316L Stainless Steel Flanges

- 310 Stainless Steel Flanges

- 310S Stainless Steel Flanges

- 309 Stainless Steel Flanges

- 301S Stainless Steel Flanges

- 316Ti Stainless Steel Flanges

- 321 Stainless Steel Flanges

- 904L Stainless Steel Flanges

- 409M Stainless Steel Flanges

- 409 Stainless Steel Flanges

- 430 Stainless Steel Flanges

- 441 Stainless Steel Flanges

- 410 Stainless Steel Flanges

- DUPLEX Stainless Steel Flanges

- DUPLEX 2205 Stainless Steel Flanges

- DUPLEX 2507 Stainless Steel Flanges

- HASTALLOY Stainless Steel Flanges

- INCONEL Stainless Steel Flanges

- X2CRNI12 Stainless Steel Flanges

- X5CRNI1810 Stainless Steel Flanges

- 253 MA Stainless Steel Flanges

- 16MO3 Stainless Steel Flanges

- Stainless Steel Strips

- Stainless Steel Shims

- Duplex Steel Plates

- Duplex Steel Plates

- Duplex Steel Plates 1.4162

- Duplex Steel Plate 1.4835

- Duplex Steel Plate 1.4362

- Duplex Steel Plate 32304

- Super Duplex Plate 32750

- Super Duplex Plate 2507

- Duplex Steel Plate 31803

- Duplex Stainless Steel 2205 Plate

- Super Duplex Plate 1.4410

- Duplex Steel Plate 2304

- Duplex Steel Plate 1.4462

- Inconel Plate

- Duplex Steel Coils

- Duplex Steel Sheets

- Duplex Steel Pipes

- Duplex Steel Pipe

- Duplex Steel ERW Pipe S31803

- Duplex Steel Welded Pipe 31803

- Super Duplex Pipe 2507

- Duplex Steel 2205 Pipe

- Duplex Steel welded Pipes 1.4462

- Duplex Steel ERW Pipe 1.4462

- Duplex Steel Pipe 31803

- Duplex Steel Pipe 1.4462

- Duplex Steel 2205 ERW Pipe

- Super Duplex Pipe 1.4410

- Duplex Steel Welded Pipe 2205

- Super Duplex Pipe 32750

- Stainless Steel Flat

- Stainless Steel Flat

- 202 Stainless Steel Flat

- 304 Stainless Steel Flat

- 304L Stainless Steel Flat

- 316 Stainless Steel Flat

- 316L Stainless Steel Flat

- 310 Stainless Steel Flat

- 310S Stainless Steel Flat

- 309 Stainless Steel Flat

- 301S Stainless Steel Flat

- 316Ti Stainless Steel Flat

- 321 Stainless Steel Flat

- 904L Stainless Steel Flat

- 409M Stainless Steel Flat

- 409L Stainless Steel Flat

- 409 Stainless Steel Flat

- 430 Stainless Steel Flat

- 441 Stainless Steel Flat

- 410 Stainless Steel Flat

- Duplex Stainless Steel Flat

- Duplex 2205 Stainless Steel Flat

- Duplex 2507 Stainless Steel Flat

- Hastelloy Stainless Steel Flat

- Inconel Stainless Steel Flat

- X2CRNI12 Stainless Steel Flat

- X5CRNI1810 Stainless Steel Flat

- 253 MA Stainless Steel Flat

- 16MO3 Stainless Steel Flat

- Stainless Steel Slitting Coils

- 301 SLITTING COIL

- 304 SLITTING COIL

- 304H SLITTING COIL

- 304L SLITTING COIL

- 316 SLITTING COIL

- 316L SLITTING COIL

- 409L-409M SLITTING COIL

- 410S SLITTING COIL

- 430 SLITTING COIL

- 441 SLITTING COIL

- Nickel 200-201 Slitting Coil

- MONEL 400 SLITTING COIL

- Jslaus SLITTING COIL

- MONEL K 500 SLITTING COIL

- INCONEL 600 SLITTING COIL

- INCONEL 625 SLITTING COIL

- INCONEL 825 SLITTING COIL

- HASTELLOY C276 SLITTING COIL

- DUPLEX 2205-31803 SLITTING COIL

- TITANIUM GRADE 1 SLITTING COIL

- TITANIUM GRADE 2 SLITTING COIL

- TITANIUM GRADE 5 SLITTING COIL

- SUPER DUPLEX 32750-32760 SLITTING COIL

- Stainless Steel Chequered Plates

- 202 Stainless Steel Chequered Plates

- 304 Stainless Steel Chequered Plates

- 316 Stainless Steel Chequered Plates

- 304L Stainless Steel Chequered Plates

- 310 Stainless Steel Chequered Plates

- 309 Stainless Steel Chequered Plates

- 316L Stainless Steel Chequered Plates

- 310S Stainless Steel Chequered Plates

- 309S Stainless Steel Chequered Plates

- 316Ti Stainless Steel Chequered Plates

- 321 Stainless Steel Chequered Plates

- 904L Stainless Steel Chequered Plates

- 430 Stainless Steel Chequered Plates

- 409M Stainless Steel Chequered Plates

- 409L Stainless Steel Chequered Plates

- 441 Stainless Steel Chequered Plates

- 410 Stainless Steel Chequered Plates

- DUPLEX Stainless Steel Chequered Plates

- DUPLEX 2205 Stainless Steel Chequered Plates

- DUPLEX 2507 Stainless Steel Chequered Plates

- HASTALLOY Stainless Steel Chequered Plates

- INCONEL Stainless Steel Chequered Plates

- X2CRNI12 Stainless Steel Chequered Plates

- X5CRNI1810 Stainless Steel Chequered Plates

- 253 MA Stainless Steel Chequered Plates

- 16MO3 Stainless Steel Chequered Plates

- Stainless Steel Chequered Sheet

- 202 Stainless Steel Chequered Sheet

- 304 Stainless Steel Chequered Sheet

- 304L Stainless Steel Chequered Sheet

- 316L Stainless Steel Chequered Sheet

- 316 Stainless Steel Chequered Sheet

- 310 Stainless Steel Chequered Sheet

- 310S Stainless Steel Chequered Sheet

- 316Ti Stainless Steel Chequered Sheet

- 309 Stainless Steel Chequered Sheet

- 301S Stainless Steel Chequered Sheet

- 321 Stainless Steel Chequered Sheet

- 409L Stainless Steel Chequered Sheet

- 409 Stainless Steel Chequered Sheet

- 430 Stainless Steel Chequered Sheet

- 304L Stainless Steel Chequered Sheet

- 409M Stainless Steel Chequered Sheet

- 441 Stainless Steel Chequered Sheet

- 410 Stainless Steel Chequered Sheet

- DUPLEX Stainless Steel Chequered Sheet

- DUPLEX 2205 Stainless Steel Chequered Sheet

- X2CRNI12 Stainless Steel Chequered Sheet

- X5CRNI1810 Stainless Steel Chequered Sheet

- Stainless Steel Welded Pipes

- 202 Stainless Steel Welded Pipes

- 304 Stainless Steel Welded Pipes

- 304L Stainless Steel Welded Pipes

- 316 Stainless Steel Welded Pipes

- 316L Stainless Steel Welded Pipes

- 310 Stainless Steel Welded Pipes

- 310S Stainless Steel Welded Pipes

- 309 Stainless Steel Welded Pipes

- 309S Stainless Steel Welded Pipes

- 316Ti Stainless Steel Welded Pipes

- 321 Stainless Steel Welded Pipes

- 904L Stainless Steel Welded Pipes

- 409M Stainless Steel Welded Pipes

- 409L Stainless Steel Welded Pipes

- 409 Stainless Steel Welded Pipes

- 430 Stainless Steel Welded Pipes

- 441 Stainless Steel Welded Pipes

- 410 Stainless Steel Welded Pipes

- DUPLEX Stainless Steel Welded Pipes

- DUPLEX 2507 Stainless Steel Welded Pipes

- HASTELLOY Stainless Steel Welded Pipes

- INCONEL Stainless Steel Welded Pipes

- X2CRNI12 Stainless Steel Welded Pipes

- X5CRNI1810 Stainless Steel Welded Pipes

- 253 MA Stainless Steel Welded Pipes

- 16MO3 Stainless Steel Welded Pipes

- Stainless Steel Seamless Pipes

- 202 Stainless Steel Seamless Pipes

- 304 Stainless Steel Seamless Pipes

- 316 Stainless Steel Seamless Pipes

- 304L Stainless Steel Seamless Pipes

- 310 Stainless Steel Seamless Pipes

- 309 Stainless Steel Seamless Pipes

- 316L Stainless Steel Seamless Pipes

- 310S Stainless Steel Seamless Pipes

- 321 Stainless Steel Seamless Pipes

- 409 Stainless Steel Seamless Pipes

- 309S Stainless Steel Seamless Pipes

- 316Ti Stainless Steel Seamless Pipes

- 430 Stainless Steel Seamless Pipes

- 441 Stainless Steel Seamless Pipes

- 409M Stainless Steel Seamless Pipes

- 409L Stainless Steel Seamless Pipes

- 410 Stainless Steel Seamless Pipes

- DUPLEX Stainless Steel Seamless Pipes

- DUPLEX 2205 Stainless Steel Seamless Pipes

- DUPLEX 2507 Stainless Steel Seamless Pipes

- HASTELLOY Stainless Steel Seamless Pipes

- INCONEL Stainless Steel Seamless Pipes

- X2CRNI12 Stainless Steel Seamless Pipes

- X5CRNI1810 Stainless Steel Seamless Pipes

- 253 MA Stainless Steel Seamless Pipes

- 16MO3 Stainless Steel Seamless Pipes

- Stainless Steel Angle

- 202 Stainless Steel Angle

- 304 Stainless Steel Angle

- 316 Stainless Steel Angle

- 316L Stainless Steel Angle

- 310 Stainless Steel Angle

- 310S Stainless Steel Angle

- 309 Stainless Steel Angle

- 301S Stainless Steel Angle

- 316Ti Stainless Steel Angle

- 321 Stainless Steel Angle

- 904L Stainless Steel Angle

- 409M Stainless Steel Angle

- 409L Stainless Steel Angle

- 409 Stainless Steel Angle

- 430 Stainless Steel Angle

- 441 Stainless Steel Angle

- 410 Stainless Steel Angle

- DUPLEX Stainless Steel Angle

- DUPLEX 2205 Stainless Steel Angle

- HASTELLOY Stainless Steel Angle

- DUPLEX 2507 Stainless Steel Angle

- INCONEL Stainless Steel Angle

- X2CRNI12 Stainless Steel Angle

- X5CRNI1810 Stainless Steel Angle

- 253 MA Stainless Steel Angle

- 16MO3 Stainless Steel Angle

- Stainless Steel Roads

- 202 Stainless Steel Rods

- 304L Stainless Steel Rods

- 316 Stainless Steel Rods

- 316L Stainless Steel Rods

- 310 Stainless Steel Rods

- 310S Stainless Steel Rods

- 309 Stainless Steel Rods

- 301S Stainless Steel Rods

- 316Ti Stainless Steel Rods

- 321 Stainless Steel Rods

- 904L Stainless Steel Rods

- 409M Stainless Steel Rods

- 409L Stainless Steel Rods

- 409 Stainless Steel Rods

- 430 Stainless Steel Rods

- 441 Stainless Steel Rods

- 410 Stainless Steel Rods

- DUPLEX Stainless Steel Rods

- DUPLEX 2205 Stainless Steel Rods

- DUPLEX 2507 Stainless Steel Rods

- HASTALLOY Stainless Steel Rods

- INCONEL Stainless Steel Rods

- X2CRNI12 Stainless Steel Rods

- X5CRNI1810 Stainless Steel Rods

- 253 MA Stainless Steel Rods

- 16MO3 Stainless Steel Rods

- ALLOY

- HASTELLOY

- INCOLOY

- MONEL

- TITANIUM

- Stainless Steel Sheet

- More Info

- Contact Us

441 Stainless Steel Flanges

Product Details:

- Coating Anti-rust Oil Coating

- Design As per ASME/ANSI B16.5

- Facing Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Process Forged / Rolled / Machined

- Color Silver

- Tolerance 0.1 mm

- Product Type 441 Stainless Steel Flanges

- Click to view more

X

441 Stainless Steel Flanges Price And Quantity

- 100 Piece

- Up to 980°C

- Chemical, Petrochemical, Oil & Gas, Power Plants, Food Industry

- Excellent against oxidation, sulfidation, and chloride attack

- Smooth, Pickled, Sand Blasted

- HRB 80 max

- 150 lbs, 300 lbs, 600 lbs, 900 lbs, 1500 lbs

- Beveled, Plain, Serrated

- AISI 441, UNS S44100

441 Stainless Steel Flanges Product Specifications

- Silver

- Forged / Rolled / Machined

- 1/2" (15 NB) to 48" (1200NB)

- Hot Rolled / Cold Rolled

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- As per ASME/ANSI B16.5

- Welded, Threaded, Slip-on, Socket Weld

- Anti-rust Oil Coating

- 0.1 mm

- ASTM A240 / ASME SA240

- Round

- 3 mm to 40 mm

- 441 Stainless Steel Flanges

- Stainless Steel

- Up to 980°C

- Chemical, Petrochemical, Oil & Gas, Power Plants, Food Industry

- Excellent against oxidation, sulfidation, and chloride attack

- Smooth, Pickled, Sand Blasted

- HRB 80 max

- 150 lbs, 300 lbs, 600 lbs, 900 lbs, 1500 lbs

- Beveled, Plain, Serrated

- AISI 441, UNS S44100

441 Stainless Steel Flanges Trade Information

- 5000 Piece Per Month

- 7 Days

Product Description

Specification

| Specifications | ASTM A182 / A240 & ASME SA182 / SA240 |

| Material | Stainless Steel 430 (UNS S43000 ) |

| Dimension | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Key Features of 441 Stainless Steel Flanges

These flanges are designed to withstand extreme environments, featuring anti-rust oil coating, high corrosion resistance, and compatibility with temperatures up to 980C. They come in multiple pressure ratings, shapes, and finishes, accommodating diverse industrial requirements. Their precise 0.1 mm tolerance and compliance with ASME/ANSI B16.5 ensure reliable performance and easy integration.

Versatile Applications Across Industries

441 Stainless Steel Flanges are widely used in sectors such as chemical processing, petrochemicals, oil & gas, power generation, and the food industry. Their durability against oxidation and chemicals makes them a preferred choice for critical piping systems and high-temperature operations.

Manufacturing and Customization Options

Offered in sizes from 1/2" to 48" and thicknesses ranging from 3 mm to 40 mm, these flanges are available with beveled, plain, or serrated ends. Surface finish options include smooth, pickled, and sand-blasted. Custom designs can be supplied according to customer or industry specifications, ensuring optimal performance in any application.

FAQ's of 441 Stainless Steel Flanges:

Q: How are 441 Stainless Steel Flanges manufactured to ensure quality and performance?

A: They are produced using forged, rolled, or machined processes under strict ASTM A240 / ASME SA240 standards. This ensures high strength, precise tolerances (0.1 mm), and excellent resistance to corrosion and high temperatures.Q: What industries commonly use 441 Stainless Steel Flanges and why?

A: Industries such as chemical, petrochemical, oil and gas, power plants, and the food sector utilize these flanges because of their outstanding heat and corrosion resistance, making them dependable in aggressive and high-temperature environments.Q: When should I choose a raised face (RF), flat face (FF), or ring type joint (RTJ) flange?

A: Select RF for most general piping systems, FF when a full, even sealing surface is required, and RTJ for high-pressure, high-temperature applications where a metal-to-metal seal is preferred.Q: Where are your 441 Stainless Steel Flanges available and which sizes can be supplied?

A: We supply and distribute across India, offering sizes from 1/2" (15NB) up to 48" (1200NB) in a variety of thicknesses between 3 mm and 40 mm to meet diverse project needs.Q: What types of surface finishes are available for these flanges?

A: Depending on application requirements, surface finishes can be smooth, pickled, or sand-blasted. These enhance resistance to scaling, improve appearance, and ensure compatibility with different industrial processes.Q: How do 441 Stainless Steel Flanges benefit piping systems exposed to harsh chemicals and temperatures?

A: With a maximum hardness of HRB 80 and resistance to oxidation, sulfidation, and chloride attack, these flanges maintain integrity in chemically aggressive and high-heat conditions, thus extending system longevity and reducing maintenance needs.Q: Can these flanges be customized according to project specifications?

A: Yes, we accommodate custom designs, ends, facings, and coatings to meet specific industry standards or unique project requirements, ensuring precise compatibility and optimal performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email