- Home Page

- Company Profile

-

Our Products

- Stainless Steel Sheet

- Stainless steel 202 Sheets

- 304 Stainless Steel Sheet

- Stainless Steel Sheet

- 430 Stainless Steel Sheet

- X2crni12 Stainless Steel Sheets

- X5crni1810 Stainless Steel Sheets

- 316 Stainless Steel Sheet

- 321 Stainless Steel Sheet

- 410 Stainless Steel Sheet

- 420 stainless steel sheet

- 904l Stainless Steel Sheet

- 202 Stainless Steel Sheets

- 301 Stainless Steel Sheets

- 304L Stainless Steel Sheets

- 316L Stainless Steel Sheets

- 310 Stainless Steel Sheets

- 310S Stainless Steel Sheets

- 309 Stainless Steel Sheets

- 309S Stainless Steel Sheets

- 316Ti Stainless Steel Sheets

- 409M Stainless Steel Sheets

- 409L Stainless Steel Sheets

- 441 Stainless Steel Sheets

- DUPLEX Stainless Steel Sheets

- DUPLEX 2205 Stainless Steel Sheets

- DUPLEX 2507 Stainless Steel Sheets

- HASTALLOY Stainless Steel Sheets

- INCONEL Stainless Steel Sheets

- X2CRNI12 Stainless Steel Sheets

- X5CRNI1810 Stainless Steel Sheets

- 253 MA Stainless Steel Sheets

- 16MO3 Stainless Steel Sheets

- Stainless Steel Coils

- 202 Stainless Steel Coil

- 316 Stainless Steel Coil

- 304L Stainless Steel Coil

- Industrial Stainless Steel Coil

- Stainless Steel Coil

- X2crni12 Stainless Steel Coils

- X5crni1810 Stainless Steel Coils

- Stainless Steel Slitting Coil

- 309 Stainless Steel Coil

- 201 Stainless Steel Coil

- 409 Stainless Steel Coil

- 410 Stainless Steel Coil

- 430 stainless steel coil

- 904l Stainless Steel Coil

- 301 Stainless Steel Coil

- 304 Stainless Steel Coil

- 316L Stainless Steel Coil

- 309S Stainless Steel Coils

- 310 Stainless Steel Coils

- 310S Stainless Steel Coils

- 316Ti Stainless Steel Coils

- 409M Stainless Steel Coils

- 409L Stainless Steel Coils

- 321 Stainless Steel Coils

- 441 Stainless Steel Coils

- DUPLEX Stainless Steel Coils

- DUPLEX 2205 Stainless Steel Coils

- DUPLEX 2507 Stainless Steel Coils

- HASTALLOY Stainless Steel Coils

- INCONEL Stainless Steel Coils

- 253 MA Stainless Steel Coils

- X2CRNI12 Stainless Steel Coils

- X5CRNI1810 Stainless Steel Coils

- 16MO3 Stainless Steel Coils

- Stainless Steel Plate

- 304 Stainless Steel Plate

- 316 Stainless Steel Plate

- Stainless Steel Plates

- Duplex Stainless Steel Plate

- 409 stainless steel plate

- 410 stainless steel plate

- 420 stainless steel plate

- 904l stainless steel plate

- 202 Stainless Steel Plate

- 304l Stainless Steel Plate

- 316L Stainless Steel Plate

- 321 Stainless Steel Plate

- 310S Stainless Steel Plate

- 309 Stainless Steel Plate

- 309S Stainless Steel Plate

- 316Ti Stainless Steel Plate

- 430 Stainless Steel Plate

- 441 Stainless Steel Plate

- DUPLEX 2205 Stainless Steel Plate

- DUPLEX 2507 Stainless Steel Plate

- INCONEL Stainless Steel Plate

- HASTALLOY Stainless Steel Plate

- X2CRNI12 Stainless Steel Plate

- X5CRNI1810 Stainless Steel Plate

- 253 MA Stainless Steel Plate

- 16MO3 Stainless Steel Plate

- Stainless Steel Pipes

- Stainless Steel Flanges

- Stainless Steel Flange

- 202 Stainless Steel Flanges

- 304 Stainless Steel Flanges

- 304L Stainless Steel Flanges

- 316 Stainless Steel Flanges

- 316L Stainless Steel Flanges

- 310 Stainless Steel Flanges

- 310S Stainless Steel Flanges

- 309 Stainless Steel Flanges

- 301S Stainless Steel Flanges

- 316Ti Stainless Steel Flanges

- 321 Stainless Steel Flanges

- 904L Stainless Steel Flanges

- 409M Stainless Steel Flanges

- 409 Stainless Steel Flanges

- 430 Stainless Steel Flanges

- 441 Stainless Steel Flanges

- 410 Stainless Steel Flanges

- DUPLEX Stainless Steel Flanges

- DUPLEX 2205 Stainless Steel Flanges

- DUPLEX 2507 Stainless Steel Flanges

- HASTALLOY Stainless Steel Flanges

- INCONEL Stainless Steel Flanges

- X2CRNI12 Stainless Steel Flanges

- X5CRNI1810 Stainless Steel Flanges

- 253 MA Stainless Steel Flanges

- 16MO3 Stainless Steel Flanges

- Stainless Steel Strips

- Stainless Steel Shims

- Duplex Steel Plates

- Duplex Steel Plates

- Duplex Steel Plates 1.4162

- Duplex Steel Plate 1.4835

- Duplex Steel Plate 1.4362

- Duplex Steel Plate 32304

- Super Duplex Plate 32750

- Super Duplex Plate 2507

- Duplex Steel Plate 31803

- Duplex Stainless Steel 2205 Plate

- Super Duplex Plate 1.4410

- Duplex Steel Plate 2304

- Duplex Steel Plate 1.4462

- Inconel Plate

- Duplex Steel Coils

- Duplex Steel Sheets

- Duplex Steel Pipes

- Duplex Steel Pipe

- Duplex Steel ERW Pipe S31803

- Duplex Steel Welded Pipe 31803

- Super Duplex Pipe 2507

- Duplex Steel 2205 Pipe

- Duplex Steel welded Pipes 1.4462

- Duplex Steel ERW Pipe 1.4462

- Duplex Steel Pipe 31803

- Duplex Steel Pipe 1.4462

- Duplex Steel 2205 ERW Pipe

- Super Duplex Pipe 1.4410

- Duplex Steel Welded Pipe 2205

- Super Duplex Pipe 32750

- Stainless Steel Flat

- Stainless Steel Flat

- 202 Stainless Steel Flat

- 304 Stainless Steel Flat

- 304L Stainless Steel Flat

- 316 Stainless Steel Flat

- 316L Stainless Steel Flat

- 310 Stainless Steel Flat

- 310S Stainless Steel Flat

- 309 Stainless Steel Flat

- 301S Stainless Steel Flat

- 316Ti Stainless Steel Flat

- 321 Stainless Steel Flat

- 904L Stainless Steel Flat

- 409M Stainless Steel Flat

- 409L Stainless Steel Flat

- 409 Stainless Steel Flat

- 430 Stainless Steel Flat

- 441 Stainless Steel Flat

- 410 Stainless Steel Flat

- Duplex Stainless Steel Flat

- Duplex 2205 Stainless Steel Flat

- Duplex 2507 Stainless Steel Flat

- Hastelloy Stainless Steel Flat

- Inconel Stainless Steel Flat

- X2CRNI12 Stainless Steel Flat

- X5CRNI1810 Stainless Steel Flat

- 253 MA Stainless Steel Flat

- 16MO3 Stainless Steel Flat

- Stainless Steel Slitting Coils

- 301 SLITTING COIL

- 304 SLITTING COIL

- 304H SLITTING COIL

- 304L SLITTING COIL

- 316 SLITTING COIL

- 316L SLITTING COIL

- 409L-409M SLITTING COIL

- 410S SLITTING COIL

- 430 SLITTING COIL

- 441 SLITTING COIL

- Nickel 200-201 Slitting Coil

- MONEL 400 SLITTING COIL

- Jslaus SLITTING COIL

- MONEL K 500 SLITTING COIL

- INCONEL 600 SLITTING COIL

- INCONEL 625 SLITTING COIL

- INCONEL 825 SLITTING COIL

- HASTELLOY C276 SLITTING COIL

- DUPLEX 2205-31803 SLITTING COIL

- TITANIUM GRADE 1 SLITTING COIL

- TITANIUM GRADE 2 SLITTING COIL

- TITANIUM GRADE 5 SLITTING COIL

- SUPER DUPLEX 32750-32760 SLITTING COIL

- Stainless Steel Chequered Plates

- 202 Stainless Steel Chequered Plates

- 304 Stainless Steel Chequered Plates

- 316 Stainless Steel Chequered Plates

- 304L Stainless Steel Chequered Plates

- 310 Stainless Steel Chequered Plates

- 309 Stainless Steel Chequered Plates

- 316L Stainless Steel Chequered Plates

- 310S Stainless Steel Chequered Plates

- 309S Stainless Steel Chequered Plates

- 316Ti Stainless Steel Chequered Plates

- 321 Stainless Steel Chequered Plates

- 904L Stainless Steel Chequered Plates

- 430 Stainless Steel Chequered Plates

- 409M Stainless Steel Chequered Plates

- 409L Stainless Steel Chequered Plates

- 441 Stainless Steel Chequered Plates

- 410 Stainless Steel Chequered Plates

- DUPLEX Stainless Steel Chequered Plates

- DUPLEX 2205 Stainless Steel Chequered Plates

- DUPLEX 2507 Stainless Steel Chequered Plates

- HASTALLOY Stainless Steel Chequered Plates

- INCONEL Stainless Steel Chequered Plates

- X2CRNI12 Stainless Steel Chequered Plates

- X5CRNI1810 Stainless Steel Chequered Plates

- 253 MA Stainless Steel Chequered Plates

- 16MO3 Stainless Steel Chequered Plates

- Stainless Steel Chequered Sheet

- 202 Stainless Steel Chequered Sheet

- 304 Stainless Steel Chequered Sheet

- 304L Stainless Steel Chequered Sheet

- 316L Stainless Steel Chequered Sheet

- 316 Stainless Steel Chequered Sheet

- 310 Stainless Steel Chequered Sheet

- 310S Stainless Steel Chequered Sheet

- 316Ti Stainless Steel Chequered Sheet

- 309 Stainless Steel Chequered Sheet

- 301S Stainless Steel Chequered Sheet

- 321 Stainless Steel Chequered Sheet

- 409L Stainless Steel Chequered Sheet

- 409 Stainless Steel Chequered Sheet

- 430 Stainless Steel Chequered Sheet

- 304L Stainless Steel Chequered Sheet

- 409M Stainless Steel Chequered Sheet

- 441 Stainless Steel Chequered Sheet

- 410 Stainless Steel Chequered Sheet

- DUPLEX Stainless Steel Chequered Sheet

- DUPLEX 2205 Stainless Steel Chequered Sheet

- X2CRNI12 Stainless Steel Chequered Sheet

- X5CRNI1810 Stainless Steel Chequered Sheet

- Stainless Steel Welded Pipes

- 202 Stainless Steel Welded Pipes

- 304 Stainless Steel Welded Pipes

- 304L Stainless Steel Welded Pipes

- 316 Stainless Steel Welded Pipes

- 316L Stainless Steel Welded Pipes

- 310 Stainless Steel Welded Pipes

- 310S Stainless Steel Welded Pipes

- 309 Stainless Steel Welded Pipes

- 309S Stainless Steel Welded Pipes

- 316Ti Stainless Steel Welded Pipes

- 321 Stainless Steel Welded Pipes

- 904L Stainless Steel Welded Pipes

- 409M Stainless Steel Welded Pipes

- 409L Stainless Steel Welded Pipes

- 409 Stainless Steel Welded Pipes

- 430 Stainless Steel Welded Pipes

- 441 Stainless Steel Welded Pipes

- 410 Stainless Steel Welded Pipes

- DUPLEX Stainless Steel Welded Pipes

- DUPLEX 2507 Stainless Steel Welded Pipes

- HASTELLOY Stainless Steel Welded Pipes

- INCONEL Stainless Steel Welded Pipes

- X2CRNI12 Stainless Steel Welded Pipes

- X5CRNI1810 Stainless Steel Welded Pipes

- 253 MA Stainless Steel Welded Pipes

- 16MO3 Stainless Steel Welded Pipes

- Stainless Steel Seamless Pipes

- 202 Stainless Steel Seamless Pipes

- 304 Stainless Steel Seamless Pipes

- 316 Stainless Steel Seamless Pipes

- 304L Stainless Steel Seamless Pipes

- 310 Stainless Steel Seamless Pipes

- 309 Stainless Steel Seamless Pipes

- 316L Stainless Steel Seamless Pipes

- 310S Stainless Steel Seamless Pipes

- 321 Stainless Steel Seamless Pipes

- 409 Stainless Steel Seamless Pipes

- 309S Stainless Steel Seamless Pipes

- 316Ti Stainless Steel Seamless Pipes

- 430 Stainless Steel Seamless Pipes

- 441 Stainless Steel Seamless Pipes

- 409M Stainless Steel Seamless Pipes

- 409L Stainless Steel Seamless Pipes

- 410 Stainless Steel Seamless Pipes

- DUPLEX Stainless Steel Seamless Pipes

- DUPLEX 2205 Stainless Steel Seamless Pipes

- DUPLEX 2507 Stainless Steel Seamless Pipes

- HASTELLOY Stainless Steel Seamless Pipes

- INCONEL Stainless Steel Seamless Pipes

- X2CRNI12 Stainless Steel Seamless Pipes

- X5CRNI1810 Stainless Steel Seamless Pipes

- 253 MA Stainless Steel Seamless Pipes

- 16MO3 Stainless Steel Seamless Pipes

- Stainless Steel Angle

- 202 Stainless Steel Angle

- 304 Stainless Steel Angle

- 316 Stainless Steel Angle

- 316L Stainless Steel Angle

- 310 Stainless Steel Angle

- 310S Stainless Steel Angle

- 309 Stainless Steel Angle

- 301S Stainless Steel Angle

- 316Ti Stainless Steel Angle

- 321 Stainless Steel Angle

- 904L Stainless Steel Angle

- 409M Stainless Steel Angle

- 409L Stainless Steel Angle

- 409 Stainless Steel Angle

- 430 Stainless Steel Angle

- 441 Stainless Steel Angle

- 410 Stainless Steel Angle

- DUPLEX Stainless Steel Angle

- DUPLEX 2205 Stainless Steel Angle

- HASTELLOY Stainless Steel Angle

- DUPLEX 2507 Stainless Steel Angle

- INCONEL Stainless Steel Angle

- X2CRNI12 Stainless Steel Angle

- X5CRNI1810 Stainless Steel Angle

- 253 MA Stainless Steel Angle

- 16MO3 Stainless Steel Angle

- Stainless Steel Roads

- 202 Stainless Steel Rods

- 304L Stainless Steel Rods

- 316 Stainless Steel Rods

- 316L Stainless Steel Rods

- 310 Stainless Steel Rods

- 310S Stainless Steel Rods

- 309 Stainless Steel Rods

- 301S Stainless Steel Rods

- 316Ti Stainless Steel Rods

- 321 Stainless Steel Rods

- 904L Stainless Steel Rods

- 409M Stainless Steel Rods

- 409L Stainless Steel Rods

- 409 Stainless Steel Rods

- 430 Stainless Steel Rods

- 441 Stainless Steel Rods

- 410 Stainless Steel Rods

- DUPLEX Stainless Steel Rods

- DUPLEX 2205 Stainless Steel Rods

- DUPLEX 2507 Stainless Steel Rods

- HASTALLOY Stainless Steel Rods

- INCONEL Stainless Steel Rods

- X2CRNI12 Stainless Steel Rods

- X5CRNI1810 Stainless Steel Rods

- 253 MA Stainless Steel Rods

- 16MO3 Stainless Steel Rods

- ALLOY

- HASTELLOY

- INCOLOY

- MONEL

- TITANIUM

- Stainless Steel Sheet

- More Info

- Contact Us

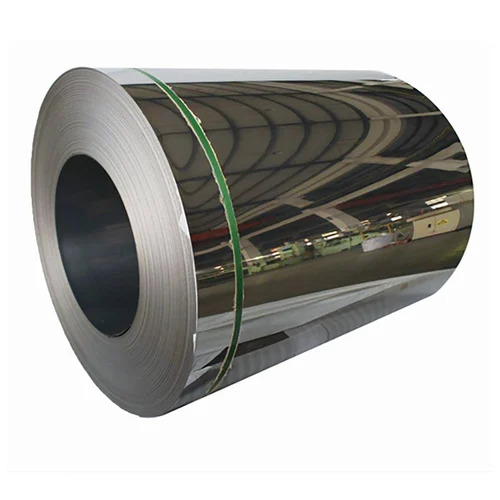

INCONEL 825 SLITTING COIL

1000 INR/Kilograms

Product Details:

- Usage Industrial

- Material INCONEL 825

- Product Type INCONEL 825 SLITTING COIL

- Coil Thickness 0.2mm 5.0mm Millimeter (mm)

- Color Silver

- Coil Length 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMERS REQUIREMENT Millimeter (mm)

- Width 33.2mm 1500mm & bove Millimeter (mm)

- Click to view more

X

INCONEL 825 SLITTING COIL Price And Quantity

- 1000 INR/Kilograms

- 100 Kilograms

INCONEL 825 SLITTING COIL Product Specifications

- Silver

- 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMERS REQUIREMENT Millimeter (mm)

- Industrial

- INCONEL 825 SLITTING COIL

- 0.2mm 5.0mm Millimeter (mm)

- INCONEL 825

- 33.2mm 1500mm & bove Millimeter (mm)

INCONEL 825 SLITTING COIL Trade Information

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- 5000 Kilograms Per Month

- 7 Days

- Within a certain price range free samples are available

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Specification of Inconel 825 Slitting Coil

|

Standards |

ASTM B424 / ASME SB424 |

|---|---|

|

Thickness |

0.2mm- 5.0mm |

|

Width |

33.2mm-1500mm & bove |

|

Length |

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMERS REQUIREMENT |

|

Hardness |

Annealed - pickled (soft), Soft, Hard, Half Hard, Quarter Hard, Spring Hard , 1/4 hard, Yi hard,3/4 hard , full hard , extra hard |

|

Test Certificate |

Chemical test, Fitting test, Alloy test, Radiography test, Macro and micro-test, Hydrostatic test, Impact test. |

|

Finish |

Cold rolled stainless steel Coil annealed & pickled 2 B Cold rolled stainless steel strips annealed & skin passed 2R Work harden for specific hardness BA/BE/ Matt Finish Cold rolled stainless steel Coils |

Inconel 825 Coil Equivelent properties

|

STANDARD |

Incoloy 825 |

|---|---|

|

WERKSTOFF NR. |

2.4858 |

|

UNS |

N08825 |

|

JIS |

NCF 825 |

|

Bs |

NA 16 |

|

GOST |

703 |

|

AFNOR |

NFE30 C20DUM |

|

EN |

NiCr 21Mo |

|

OR |

XH38 BT |

Inconel 825 Coils Chemical Composition

|

STANDARD |

825 |

|---|---|

|

C |

0.05 max |

|

Mn |

1.00 max |

|

Si |

0.5 max |

|

S |

0.03 max |

|

Cu |

1.50 - 3.00 |

|

Fe |

22.00 min |

|

Cr |

19.50 - 23.50 |

|

Ni |

38.00 -46.00 |

|

Al |

0.02 max |

|

Ti |

0.06 - 1.20 |

|

Tisco Inconel 825 Coil |

Inconel 825 Perforated Coil |

|---|---|

|

Inconel 825 Coils |

ASTM B443 Inconel 825 Coil |

|

Jindal Inconel 825 Coils |

SS DIN 2.4858 Coil |

|

Inconel 825 UNS N08825 Coil |

ASTM B424 Chequered Inconel 825 Coil |

|

Inconel 825 Embossed Coil |

Outokumpu Inconel 825 Coil |

|

ThyssenKrupp Inconel 825 Coils |

ASTM B424 Inconel 825 Coils |

|

Aperam Inconel 825 Coils |

ASME SB424 Inconel 825 Coil |

Exceptional Corrosion Resistance

INCONEL 825 Slitting Coils are engineered to withstand harsh environments, making them indispensable in industries such as chemical processing and oil & gas. The alloy's composition provides excellent resistance to pitting, stress-corrosion cracking, and oxidizing acids, ensuring longevity and reliability for critical applications.

Wide Customizability

These slitting coils can be manufactured to customer-specified lengths, widths, and thicknesses, ranging from 0.2mm to 5.0mm in thickness and up to 1500mm in width or more. This flexibility in dimensions ensures that both small and large-scale industries can optimize their processes and reduce material wastage.

Preferred Choice Across Industries

Serving as a one-stop solution for dealers, manufacturers, traders, and suppliers, INCONEL 825 Slitting Coils are widely distributed and utilized throughout India. Their versatility and high performance make them an excellent choice for industrial applications that demand strict standards for strength and durability.

FAQ's of INCONEL 825 SLITTING COIL:

Q: What are the standard sizes available for INCONEL 825 slitting coils?

A: INCONEL 825 slitting coils are available in standard lengths of 2000mm, 2440mm, 3000mm, 5800mm, and 6000mm, with customizable dimensions upon request. The thickness ranges from 0.2mm to 5.0mm, and widths span from 33.2mm to 1500mm and beyond.Q: How can customers order INCONEL 825 slitting coils to fit their precise requirements?

A: Customers can specify their required length, thickness, and width, and the coils will be slit and supplied accordingly. Most suppliers accommodate custom orders to match unique industrial needs, ensuring a tailored fit for each project.Q: What are the main industrial uses for INCONEL 825 slitting coil?

A: These coils are extensively utilized in chemical processing, oil and gas, and marine industries due to their remarkable resistance to corrosive environments, making them ideal for manufacturing components that must endure extreme conditions.Q: When is INCONEL 825 preferred over other materials for slitting coils?

A: INCONEL 825 is chosen when high mechanical strength and superior corrosion resistance are crucial, particularly in environments exposed to acids, alkalis, or chloride ions where standard stainless steels may fail.Q: Where are these INCONEL 825 slitting coils supplied and distributed?

A: These coils are supplied across India through an extensive network of dealers, distributors, manufacturers, and wholesalers, servicing both local and national industrial demands.Q: What is the process for manufacturing INCONEL 825 slitting coils?

A: The process starts with casting and hot/cold rolling INCONEL 825 sheets, followed by precision slitting into coils with the required widths and thicknesses. Each coil is then inspected for quality and finished to a silver color.Q: What are the key benefits of using INCONEL 825 slitting coil in my operations?

A: Key benefits include exceptional resistance to corrosion, excellent mechanical properties, and the availability of custom sizes, which together enhance the reliability and efficiency of industrial operations in demanding environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email